Research and development activities in the Group again concentrated on two areas in 2012: expanding our product portfolio and improving the functionality, quality, safety and environmental compatibility of Group products.

Focus of our research and development activities

Research and development focused in particular on the ecological and economic alignment of our vehicle portfolio. The Group Chief Officer who manages and coordinates all Group activities concerning the environment, energy and new business areas expanded his work during the reporting period so as to achieve the greatest possible synergies.

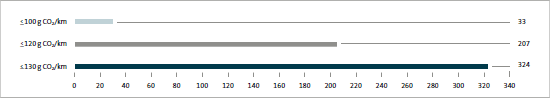

The Volkswagen Group has set itself the target of cutting the average CO2 emissions of its new European passenger car fleet to under 120 grams of CO2 per kilometer by 2015. We already reduced this figure over the past five years by 25 grams of CO2 per kilometer to 134 grams of CO2 per kilometer. From 2012 onwards, the CO2 emissions for vehicle manufacturers’ new European passenger car fleets are regulated by law. For 2012, 65% of the new vehicle fleet had to have emissions below the statutory value of 130 grams of CO2/km: the figure for the Volkswagen Group in the reporting period was 120 g CO2/km. We currently offer a total of 324 model variants that emit less than 130 grams of CO2 per kilometer. For 207 model variants, we are already below the threshold of 120 grams of CO2 per kilometer. Of these, 33 model variants are below 100 grams of CO2 per kilometer (see the following chart).

CO2 EMISSIONS – STATUS QUO

Number of vehicles

We also concentrated on communication technologies in 2012, in particular vehicle-to-vehicle and vehicle-to-infrastructure communication. Exchanging information with other road users and with infrastructures, and therefore connecting vehicles to their environment, will be a key component of the future of automobility.

Lightweight construction for large series is becoming increasingly important to achieve ambitious CO2 reduction targets in the automotive industry. The mutual cooperation between the Volkswagen Group’s research and development units and the production and components departments is accelerating research into lightweight construction and its future production technologies. The entire value chain, from the carbon fiber through the production process down to the manufacturing of functional lightweight construction components – including the conceptional skills for designing parts and recycling – is modeled in the “Open Hybrid LabFactory” research factory. International technology leaders and research pioneers are in charge of all the steps in the process and are incorporating their combined expertise into developing the jointly used research factory.

Another of Volkswagen’s areas of expertise is virtual technologies. In the past, these were successfully used to speed up and improve the vehicle development, production, or service process. However, these technologies are also becoming available for automotive customers, with end products that are more high-performance than ever, such as smartphones. The primary focus is on augmented reality technology, in which the real world is recognized and enriched with virtual information. Smartphones are using this technology to become innovative owner manuals: customers can film a part of the vehicle on their smartphone and receive multimedia information about how to use it. The Audi brand is the first to put this technology into the “Audi A1 eKurzinfo” series smartphone application. The Volkswagen Group’s research and development team are working on other applications for comparable uses in order to safeguard our leading position in this area.

In August 2012, the Volkswagen Group of America opened a state-of-the-art research and development center in California. Drive technologies and vehicles from several Group brands will be tested and optimized here. At the heart of this complex is the climate-controlled emissions lab, which tests exhaust emissions and performance at extreme temperatures. Porsche is expanding its research and development center in Weissach, near Stuttgart, with a state-of-the-art wind tunnel and a design studio, among other things. ŠKODA is adding 21 new engine and component test beds to its technology and development center in Cesana, near the corporate headquarters in Mladá Boleslav – one of the largest investments currently being made in development in the Czech Republic.

Innovative products captivate our customers

The “Automotive INNOVATIONS Awards” are presented every year to vehicle manufacturers by the Center of Automotive Management, an independent organization that conducts empirical research on automobiles and mobility. The Volkswagen Group underlined its lead with wins in the categories “Most Innovative Automotive Company”, “Best Manufacturer: Conventional Drives” and “Best Manufacturer: Vehicle Concepts” in fiscal year 2012.

In the following paragraphs we present selected innovations – new models, powertrains and systems launched during the past fiscal year.

Cylinder deactivation was used in a four-cylinder turbo engine for the first time in the new Polo BlueGT. This technology automatically deactivates the second and third cylinders under light and medium load conditions without the driver noticing. This significantly reduces the 1.4 TSI engine’s fuel consumption. The sporty Polo BlueGT’s strong engine and seven-speed  direct shift gearbox use an average of only 4.5 l of fuel per 100 km and produce 105 g/km of CO2 per kilometer.

direct shift gearbox use an average of only 4.5 l of fuel per 100 km and produce 105 g/km of CO2 per kilometer.

Following the Touareg Hybrid, the Jetta Hybrid was the second Volkswagen in 2012 to have a drivetrain module with both a petrol engine and an electric motor under its bonnet. The combination of a 1.4 TSI engine (110 kW/150 PS), an electric motor (20 kW) and a seven-speed direct shift gearbox makes driving both dynamic and economical.

After the up! was first introduced in 2011, the Volkswagen Passenger Cars brand presented two more versions of the small car in the reporting period. The four-door up! lets even very tall people get in and out of the vehicle comfortably thanks to its wide-opening doors. An optional extra is a panoramic roof, something which is unusual for this vehicle segment. The eco up! – powered by a  CNG engine with 50 kW (68 PS) – leads the pack with CO2 emissions of 79 g/km.

CNG engine with 50 kW (68 PS) – leads the pack with CO2 emissions of 79 g/km.

The Volkswagen Passenger Cars brand’s innovative highlight in the reporting period was the all-new Golf, which is based on the  Modular Transverse Toolkit (MQB). It is up to 100 kg lighter and 23% more efficient than its predecessor.

Modular Transverse Toolkit (MQB). It is up to 100 kg lighter and 23% more efficient than its predecessor.

The newly developed generations of petrol and diesel motors ranging from 63 kW (85 PS) to 169 kW (230 PS) make it fun to drive. Among other things, they feature a start-stop system and battery regeneration mode to recuperate brake energy as standard and are therefore particularly fuel-efficient. For example, active cylinder management helps the 1.4 TSI petrol engine to use an average of 4.7 l per 100 km. The new air conditioning system design also helps to reduce fuel consumption. A large number of new safety and assistance systems are also available for the Golf. Some examples are the Front Assist with an integrated city emergency braking function, fatigue detection, an electronic differential lock as standard, the Lane Assist lane keeping assistant, road sign recognition and the latest generation of the Park Assist automatic parking assistant, which warns against obstacles with a graphical 360 degree display. The multi-collision brake, which comes as standard and was awarded a “Golden Angel” in 2012 from German automobile club ADAC, slows the vehicle down after an accident so as to reduce the remaining energy and thus avoid typical secondary accidents. Additional technologies such as the progressive steering system, a driver profile selection with five programs and the new information and entertainment system with a display that reacts to hand movements via a proximity sensor round off the specification package. On the outside, the Golf features timeless design cues with horizontal front lines, a pronounced C-pillar and perfectly formed, minimalist styling.

Audi celebrated the world premiere of the third-generation Audi A3 in fiscal year 2012. It was the first vehicle in the Volkswagen Group to be based on the Modular Transverse Toolkit and has benefited from the associated reduction in complexity, costs and time required for development. The new A3 Sportback is up to 90 kg lighter than its predecessor and, as a vehicle in the premium compact class, can be fitted with a range of driver assistance systems such as Audi’s adaptive cruise control. This maintains a preset distance between the car and the vehicle ahead up to a speed of 200 km/h by autonomously accelerating and decelerating.

Audi expanded its ranges in 2012 with the new A6 hybrid and A8 hybrid models. Both models have a 2.0 TFSI engine and an electric motor and can be powered by both the combustion engine and electric motor, as well as in hybrid mode. During the lag phases, the vehicles recuperate energy while strong acceleration activates both engines. With a total output of 180 kW (245 PS), the A6 hybrid only uses 6.2 l of super grade fuel, while CO2 emissions are only 145 g/km.

The new SEAT Leon is the first vehicle in the A segment to use full LED headlight technology. This supports the vehicle’s exceptional design while increasing its functionality. The Leon represents a revolution for the SEAT brand in terms of quality and appeal – particularly in its interior. The Leon is also based on the Modular Transverse Toolkit. The resulting 90 kg weight saving compared with the previous model gives it more dynamic handling and has a positive impact on fuel consumption. The optimized and finely tuned chassis combines comfort and a sporty design, in line with the SEAT brand image. A comprehensive assistance and information system rounds off the entire package.

Scania presented its newly developed, innovative 9 and 13 liter diesel engines as well as two new high-performance gas engines in fiscal year 2012. These efficient engines meet all the requirements of the future Euro 6 emission standard.

In fiscal 2012, MAN celebrated the world premiere of the new TG family of trucks, which comply with the future Euro 6 emission standard. These boast fuel consumption just as low as their particularly efficient predecessors.