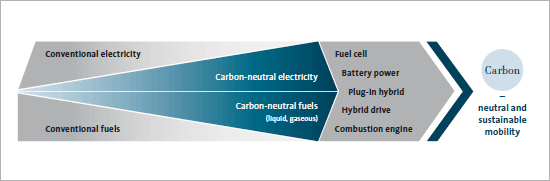

The use of efficient, sustainable drivetrains is a highly important strategic issue for Volkswagen. The Group is not only working to continuously optimize its existing drivetrains but is also – as in the past – pursuing a variety of alternative drive concepts, and especially electric traction. At present, our customers primarily choose conventional engines to drive their vehicles. Electrified drive technology and conventional combustion engines will continue to coexist in the future on the road to carbon-neutral, sustainable mobility. This coexistence will be flanked by a steady increase in the share of carbon-neutral energy sources, be it in the form of renewable power for electric vehicles, the production of carbon-neutral biofuels, or synthetic natural gas. The latter is produced in electrolysis and methanation plants fueled by wind-powered electricity. It can be used among other things to power specially developed  CNG combustion engines. It addition, the Group is examining innovative renewable fuels that bind CO2 during production and that put carbon-neutral mobility within grasping distance.

CNG combustion engines. It addition, the Group is examining innovative renewable fuels that bind CO2 during production and that put carbon-neutral mobility within grasping distance.

Particularly in global growth markets such as Russia, India and the Far East, combustion engines look set from today’s perspective to serve as the broad basis for drive technology in the coming years. Given the need to use resources responsibly, it is crucial to optimize combustion engines here so as to facilitate sustainable, forward-looking mobility. In response to this challenge, the Volkswagen Group has developed entirely new generations of petrol and diesel engines that are being incorporated successively into its vehicle range. These drivetrains were used in the successor models for the Audi A3 and Golf for the first time in 2012.

All the new engines feature turbocharging, direct injection and a start-stop system as a standard feature. In addition, they make use of other fuel-saving technologies such as intelligent thermomanagement for reducing mechanical and energy losses,  recuperation, demand-driven auxiliary power unit management and variable valve management. Many Group vehicles with petrol engines started using active cylinder management for the first time in 2012, which automatically switches off individual cylinders without the driver noticing when they are not needed. This innovative technology cuts fuel consumption by up to 0.5 l per 100 km, depending on the engine involved. Active cylinder management is used in the Polo BlueGT, the new Golf, the Audi A3, S6, S7 Sportback and S8 models and the Bentley Continental.

recuperation, demand-driven auxiliary power unit management and variable valve management. Many Group vehicles with petrol engines started using active cylinder management for the first time in 2012, which automatically switches off individual cylinders without the driver noticing when they are not needed. This innovative technology cuts fuel consumption by up to 0.5 l per 100 km, depending on the engine involved. Active cylinder management is used in the Polo BlueGT, the new Golf, the Audi A3, S6, S7 Sportback and S8 models and the Bentley Continental.

Driver profile selection is another means of reducing fuel consumption. It is already integrated into several Volkswagen Group vehicles and was included in a volume model – the new generation of the Golf – for the first time in 2012. The eco, normal and sport modes selected by the driver are used in engine and gear management and to switch auxiliary power units and the air conditioning on and off as necessary.

The Group’s efficiency models show what can already be achieved today by combining efficient conventional drives and vehicle innovations such as low rolling resistance tires and aerodynamic measures. At Volkswagen, they are available under the “BlueMotion” label, at ŠKODA they are known as the “GreenLine” models and at SEAT they go by the name of “ECOMOTIVE”. With CO2 emissions of 87 g/km and fuel consumption of only 3.3 l per 100 km, the Polo BlueMotion is one of the most environmentally-friendly and economical five-door vehicles in the world. The new Golf BlueMotion – available from mid–2013 onwards – with its new 1.6 TDI engine will have an average fuel consumption of only 3.2 l per 100 km and CO2 emissions of a mere 85 g/km. The ŠKODA Octavia GreenLine that will be introduced in 2013 emits only 89 g/km CO2 and uses 3.4 l diesel per 100 km. The eco up! that was launched at the end of 2012 has a 1.0 CNG engine and CO2 emissions of merely 79 g/km.

THE ROAD TO CARBON-NEUTRAL MOBILITY

What is more, the Audi and Porsche brands provide impressive proof that premium-segment diesel engines can be both dynamic and economical. The twin turbocharged 3.0 TDI engine in the new Audi SQ5 TDI has an output of 230 kW (313 PS) and uses a mere 6.8 l of diesel per 100 km. Porsche’s Cayenne S diesel offers another example of twin turbocharger technology in the form of its 4.2 l V8 diesel engine, which has an output of 281 kW (382 PS). It uses a mere 8.3 l of diesel per 100 km.

Our successful TSI, TFSI and TDI engines, ideally combined with the Group’s innovative direct shift gearboxes, offer a good starting point for efficient vehicle propulsion now and in the future. They can be combined with electrical components on a modular basis to produce  hybrid drives. Plug-in versions of these vehicles can be recharged via electrical outlets and – depending on the model concerned – can cover between 20 and 80 km in purely electric mode.

hybrid drives. Plug-in versions of these vehicles can be recharged via electrical outlets and – depending on the model concerned – can cover between 20 and 80 km in purely electric mode.

When it comes to drive electrification, hybrids – and particularly  plug-in hybrids – are a core topic for the Volkswagen Group, since these are currently the best way of supplementing petrol and diesel engines. They combine the benefits of two technologies and hence meet a number of customer expectations: an unlimited range thanks to their combustion engines, an attractive electric drive unit for day-to-day urban use, no restrictions on speed, hill-climbing ability, or trailer loads and substantial potential for reducing CO2 emissions. As a result, Volkswagen Group is mounting a major new push for this technology, a key element of which is its integration into the modular toolkit strategy. This underscores the importance of e-mobility within the Group, giving it a firm, long-term place in its product strategy. Combined drives are already available today in a large number of vehicle classes in the form of the hybrid versions of the Jetta, Touareg, Audi Q5, Audi A6, Audi A8, Porsche Cayenne S and Porsche Panamera S models.

plug-in hybrids – are a core topic for the Volkswagen Group, since these are currently the best way of supplementing petrol and diesel engines. They combine the benefits of two technologies and hence meet a number of customer expectations: an unlimited range thanks to their combustion engines, an attractive electric drive unit for day-to-day urban use, no restrictions on speed, hill-climbing ability, or trailer loads and substantial potential for reducing CO2 emissions. As a result, Volkswagen Group is mounting a major new push for this technology, a key element of which is its integration into the modular toolkit strategy. This underscores the importance of e-mobility within the Group, giving it a firm, long-term place in its product strategy. Combined drives are already available today in a large number of vehicle classes in the form of the hybrid versions of the Jetta, Touareg, Audi Q5, Audi A6, Audi A8, Porsche Cayenne S and Porsche Panamera S models.

Volkswagen will also ring in the age of pure-play e-mobility in 2013 with the market launch of the e-up! and then the e-Golf. The Group brands performed extensive international fleet trials with purely electric vehicles and a large number of different customer groups in fiscal year 2012 and were able to optimize the technology, its suitability for daily use and user requirements for later series production. At present, for example, ten ŠKODA Octavia Green E Line vehicles are in use at a number of customers in the Czech Republic. However, a number of challenges still have to be mastered before electric vehicles can be launched onto the wider market. Developing high- performance batteries and building up technological expertise in the area of battery chemistry are both vital to increasing the range and hence the attractiveness of electric vehicles. Another challenge is integrating electric cars into the existing infrastructure. A large number of questions still need to be answered together with the government, municipal authorities and utilities with respect to the recharging strategy to be adopted (“smart grid”), how to construct an end-to-end infrastructure, particularly of rapid charging stations, and how to book charging points and bill the electricity provided. In the Volkswagen Group’s opinion, the intelligent combination of the automotive, power generation and telecommunications sectors offers the opportunity to ease the transition to e-mobility for customers, or to make it attractive for them – for example by providing new services and business models, such as mobile online services that give details on battery charge levels and recharging options.

Volkswagen will manufacture not only the bodywork but also the core components of electric cars – the electric motor and the battery system. The Kassel plant has been designated to manufacture the motors, while the battery modules will be assembled into battery systems in the Braunschweig facility.

This basic mix of conventional and alternative technologies and Volkswagen’s modular toolkit strategy, which allows innovations to be incorporated rapidly into different vehicles, means that the Group is optimally positioned to meet the challenges that the future will bring.