A car has the greatest ecological impact when it is being used. However, there is still tremendous potential for production to be more sustainable as well.

The individual Group brands launched overarching initiatives to make production more efficient. These initiatives identify potential, develop strategies and solutions, and implement measures. Examples include the Volkswagen Passenger Cars brand’s “Think Blue. Factory.” initiative and the ŠKODA brand’s “GreenFuture” initiative.

Examples from the reporting period illustrate clearly that these initiatives are effective: a new demand-driven way to sequence the generation of compressed air is cutting usage by 15% at the Chattanooga site. In the Russian Kaluga plant, hot waste gases from the boiler house are vented through an additional heat exchanger. This recovers heat, which is then used for the hot water system, saving approximately 1,000 megawatt hours (MWh) of energy each year and reducing annual CO2 emissions by 485 tonnes. A new body shell production facility was established in 2012 at the Emden site. Volkswagen uses the approximately 5,000 foundation piles, bored into the ground, to store energy: in the summer, the piles store the waste heat from the welding machines in the ground; in the winter, the stored heat is used to heat the production sheds.

Volkswagen relies on generating its own energy from renewable sources at many of its locations so as to reduce the proportion of additional primary energy it purchases. For example, the photovoltaic installation on the roof of the production facility for body shells for the Audi A3 in Ingolstadt generates around 460 MWh of electricity a year. Additional systems came into operation in 2012, for example in Braunschweig and Hanover (each generating 420 MWh a year). Another solar energy system with over 33,000 solar panels will be installed at the beginning of 2013 at Volkswagen’s Chattanooga location. A new, 17,000 m2 solar power plant reduced CO2 emissions by 30% at the Lamborghini brand’s Italian location in Sant’Agata Bolognese in the reporting period.

Warm forming of sheet steel is an example of a case where saving energy can also sometimes mean that more energy is used initially. This process forms and heat-treats the steel by cooling it in seconds from 950°C to about 175°C in a single step. This means that the material can be stretched up to six times more than steel used in conventional deep drawing. The result is thinner and lighter components that are just as stable as conventional parts. Although more energy is used at first for this warm forming process, the energy that the vehicle requires over its overall life cycle is lower because it weighs less. The new Golf, for example, is produced using such parts.

Volkswagen also set new milestones in 2012 in terms of materials efficiency. At the Wolfsburg site, the width of the coils – flat-rolled steel strips that are used to make parts for the body – was reduced. This creates significantly less waste. Additionally, the tools, the component geometries and plates nesting were optimized to improve materials utilization. The new Golf generates 15% less waste during production than its predecessor. Each year, optimization measures save around 73,000 tonnes of steel in the aggregate for other models.

In the paintshop at the Wolfsburg location, 48 of the latest generation of painting robots went into operation in the reporting period. The robots are equipped with color changing and application systems, which cut the amount of paint and cleaning products used as well as paint waste by up to 50%, corresponding to a saving of €800,000. In addition, the robots require up to 20% less compressed air and significantly less energy than their predecessors. This avoids 120 tonnes of CO2 emissions annually.

VOC EMISSIONS (VOLATILE ORGANIC COMPOUNDS)*

in grams per vehicle

FRESH WATER CONSUMPTION*

in cubic meters per vehicle

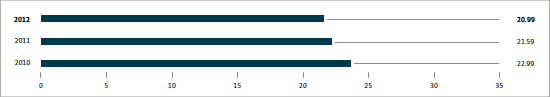

DISPOSABLE WASTE*

in kilograms per vehicle

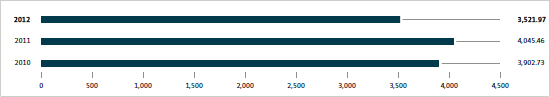

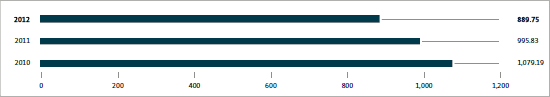

CO2 EMISSIONS*

in kilograms per vehicle

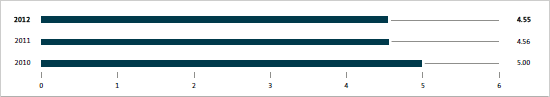

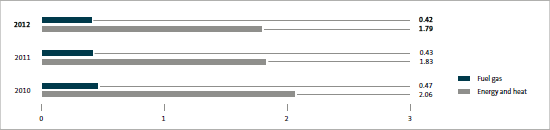

ENERGY CONSUMPTION*

in megawatt hours per vehicle

* Production of passenger cars and light commercial vehicles.